Solutions to Control Hazards

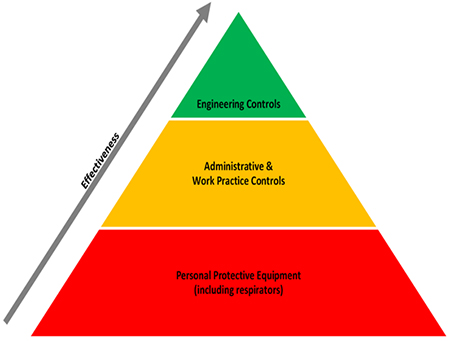

Ergonomics pyramid – Showing Engineering Controls at the top, Administrative and Work Practice Controls in the middle, and Personal Protective Equipment (including respirators) at the base. An arrow is going from bottom to top, along the side of the pyramid, labeled Effectiveness.

Many industries have successfully implemented ergonomic solutions in their facilities as a way to address their workers’ MSD injury risks. These interventions have included modifying existing equipment, making changes in work practices and purchasing new tools or other devices to assist in the production process. Making these changes has reduced physical demands, eliminated unnecessary movements, lowered injury rates and their associated workers’ compensation costs, and reduced employee turnover. In many cases, work efficiency and productivity have increased as well. Simple, low-cost solutions are often available to solve problems. Use the information on this page to see what has worked for others in your industry or in other industries.

Overview of Controls for MSD Hazards

To reduce the chance of injury, work tasks should be designed to limit exposure to ergonomic risk factors. Engineering controls are the most desirable, where possible. Administrative or work practice controls may be appropriate in some cases where engineering controls cannot be implemented or when different procedures are needed after implementation of the new engineering controls. Personal protection solutions have only limited effectiveness when dealing with ergonomic hazards.

| Type of Control | Workplace Examples |

|---|---|

| Engineering Controls (implement physical change to the workplace, which eliminates/reduces the hazard on the job/task) | Use a device to lift and reposition heavy objects to limit force exertionReduce the weight of a load to limit force exertionReposition a work table to eliminate a long/excessive reach and enable working in neutral posturesUse diverging conveyors off a main line so that tasks are less repetitiveInstall diverters on conveyors to direct materials toward the worker to eliminate excessive leaning or reachingRedesign tools to enable neutral postures |

| Administrative and Work Practice Controls (establish efficient processes or procedures) | Require that heavy loads are only lifted by two people to limit force exertionEstablish systems so workers are rotated away from tasks to minimize the duration of continual exertion, repetitive motions, and awkward postures. Design a job rotation system in which employees rotate between jobs that use different muscle groupsStaff “floaters” to provide periodic breaks between scheduled breaksProperly use and maintain pneumatic and power tools |

| Personal Protective Equipment (use protection to reduce exposure to ergonomics-related risk factors) | Use padding to reduce direct contact with hard, sharp, or vibrating surfacesWear good fitting thermal gloves to help with cold conditions while maintaining the ability to grasp items easily |