Lockout/Tagout

Workers conducting equipment maintenance or service may be seriously injured or killed if hazardous energy is not properly controlled. Injuries resulting from the failure to control hazardous energy during maintenance activities can be serious or fatal, and may include electrocution, burns, crushing, cutting, lacerating, amputating, or fracturing body parts, and others.

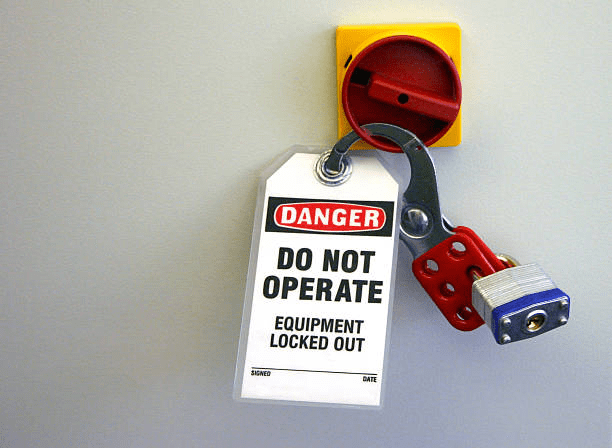

Warehouse operations need a lockout/tagout program (see 29 CFR 1910.147) to ensure that before any worker performs any servicing or maintenance, the machine or equipment is isolated from the energy source and rendered inoperative. The program must include three core components: energy control procedures, employee training, and periodic inspections.

Workers required to perform these operations should be trained, and all workers should have a working knowledge of the program. Employers should also evaluate the procedures at least annually to ensure they are being followed and that they meet OSHA requirements.

Below are some OSHA resources that can assist in protecting workers from uncontrolled releases of hazardous energy.

- Control of Hazardous Energy (Lockout/Tagout). OSHA Safety and Health topic page on hazards associated with the unexpected startup or release of stored energy during machine and equipment servicing and maintenance.

- Lockout/Tagout eTool. An interactive, web-based training tool designed to expand the user’s knowledge of lockout/tagout.

- Control of Hazardous Energy – Enforcement and Inspection Procedures. Directive CPL 02-00-147; February 11, 2008.

- OSHA Fact Sheet: Lockout/Tagout.

LOTO Safety: 7 Steps of lockout tagout

- Prepare for shutdown.

- Notify all affected employees of the activities and equipment involved.

- Shut down the equipment.

- Isolate the equipment from the hazardous energy source.

- Dissipate residual energy.

- Apply applicable lockout or tagout devices.

You must be logged in to post a comment.