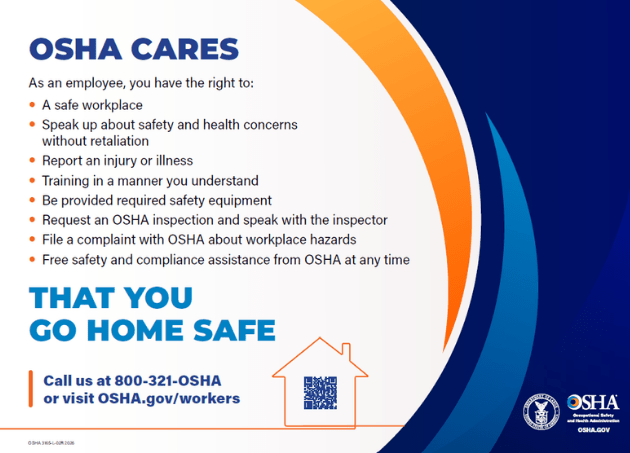

Know Your Rights

Federal law entitles you to a safe workplace. Your employer must keep your workplace free of known health and safety hazards. You have the right to speak up about hazards without fear of retaliation. You also have the right to:

- Receive workplace safety and health training in a language you understand

- Work on machines that are safe

- Receive required safety equipment, such as gloves or a harness and lifeline for falls

- Be protected from toxic chemicals

- Request an OSHA inspection, and speak to the inspector

- Report an injury or illness, and get copies of your medical records

- Review records of work-related injuries and illnesses

- See results of tests taken to find workplace hazards

Did You Know?

Federal law requires employers to protect workers against heat hazards. A new OSHA Hazard Alert lays out employer responsibilities, worker rights, and OSHA’s current heat enforcement efforts. For more information and resources to keep workers safe, visit OSHA’s Heat Illness Prevention webpage.

Tornado Preparedness and Response

Response/Recovery

In the aftermath of a tornado, workers may be involved in a variety of response and recovery operations. The following are general guidelines that may be applicable to workers involved in assessing and/or cleaning up the damage to their worksite. However, some operations, such as utility restoration, cleaning up spills of hazardous materials, and search and rescue, should only be conducted by workers who have the proper training, equipment and experience.

Potential Hazards

Response and recovery work in tornado-impacted areas presents safety and health hazards that should be properly identified, evaluated, and controlled in a systematic manner to reduce or eliminate occupational safety and health risks to response and recovery workers. Some of the specific hazards associated with working in the aftermath of tornadoes include:

- Hazardous driving conditions due to slippery and/or blocked roadways

- Slips and falls due to slippery walkways

- Falling and flying objects such as tree limbs and utility poles

- Sharp objects including nails and broken glass

- Electrical hazards from downed power lines or downed objects in contact with power lines

- Falls from heights

- Burns from fires caused by energized line contact or equipment failure

- Exhaustion from working extended shifts

- Heat and Dehydration.

General Precautions

- Continue to monitor your local radio or television stations for emergency information and the potential of additional storms. Be aware of possible structural, electrical, or gas-leak hazards.

- If such hazards are identified, report them to the proper local authorities and/or utility.

- Do not touch downed power lines or objects in contact with downed power lines.

- Wear proper clothing when walking on or near debris, including boots and gloves.

- Be careful around sharp objects, including nails and broken glass.

- Use the proper safety precautions when operating generators, chainsaws, or other power tools.

- Take steps to prevent heat illnesses and dehydration.

See the Centers for Disease Control and Prevention (CDC) website for additional precautions to take after a tornado.

Fact Sheets and Quick Cards

OSHA has the following materials to assist employers with assessing and controlling the hazards common to most response and recovery work in tornado-impacted areas.

- Search and Rescue

- Portable Generator Safety

- Chain Saw Safety | Spanish

- Demolition and Cleanup

- Work Zone Traffic Safety

- Downed Electrical Wires

- Heat StressFor additional information see the Occupational Heat Exposure Safety and Health Topics page.

For more information, see other Emergency Response Resources from the National Institute for Occupational Safety and Health (NIOSH) or for a full list of related materials, see the Additional Resources page.

ESSO Members,

If there is a safety question you would like an answer to or safety topics you would like discussed, please reach out to the Safety Committee at safetycommittee@u-46.org.

ESSO Members,

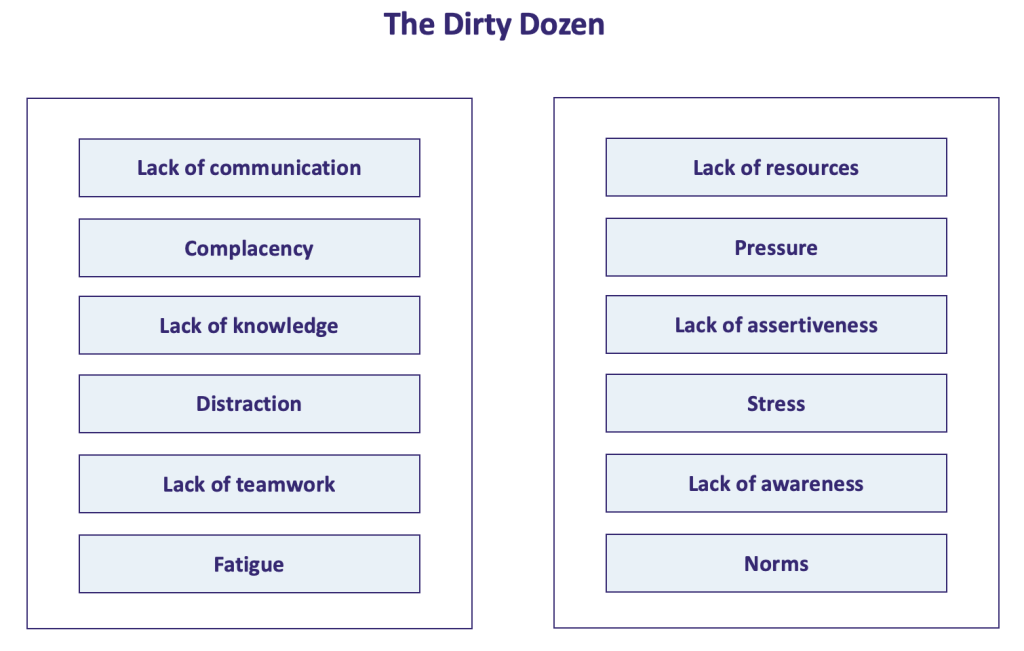

Here are 12 topics that are the leading causes for accidents and injuries in the workplace. Please be aware of your work surroundings and Stay Safe.

What are the 3 primary hazards when working with electricity?

The major hazards associated with electricity are electrical shock, fire and arc flash.

Emergency Planning

Emergencies and disasters can strike anywhere and at any time, bringing workplace injuries and illnesses with them. Employers and workers may be required to deal with an emergency when it is least expected and proper planning before an emergency is necessary to respond effectively.

A workplace emergency is a situation that threatens workers, customers, or the public; disrupts or shuts down operations; or causes physical or environmental damage. The Getting Started section of OSHA’s Emergency Preparedness and Response Safety and Health Topics Page provides a listing of all of the specific hazards for which the agency currently has information available on its website, as well as links to general emergency preparedness and response guidance.

Warehousing employers should have an emergency plan that describes (1) what is expected of workers in the event of an emergency, including provisions for emergency exit locations and evacuation procedures, (2) procedures for accounting for all workers and visitors, and (3) the location and use of fire extinguishers and other emergency equipment.

Below are emergency planning considerations for warehousing operations.

Exits and Exit Routes (see 29 CFR 1910.37)

- Keep safeguards designed to protect workers during an emergency (e.g., sprinkler systems, alarm systems, fire doors, exit lighting) in proper working order.

- Ensure exit signs are illuminated and clearly visible at all times.

- Keep exit routes and exits free and unobstructed; ensure that exit doors are not locked or blocked.

- Ensure exit routes are adequately lit.

- Exit routes must not go through a room that can be locked, e.g., a bathroom, nor may it lead into a dead-end corridor.

- Mark doorways or passages along an exit route that could be mistaken for an exit with “Not an Exit” or language identifying their actual use, e.g., “closet.”

- If the direction of travel to the nearest exit is not immediately apparent, post signs along the exit access indicating the direction of travel to the nearest exit.

Fire Hazards

If portable fire extinguishers are available and intended for worker use (see 29 CFR 1910.157):

- Ensure that the fire extinguishers are adequate and appropriate for the hazard present in the facility.

- Mount, locate and identify fire extinguishers so that they are readily accessible in an emergency.

- Ensure fire extinguishers are fully charged and operable.

- Conduct a visual inspection of all fire extinguishers monthly and conduct maintenance annually.

- Train workers on the general principles of fire extinguisher use and the hazards involved with incipient stage firefighting; retrain workers at least annually.

Medical Services and First Aid (see 29 CFR 1910.151)

- Ensure a trained first-aid provider is on-site and maintain adequate first-aid supplies. (Note: Employers may instead determine that these services will be provided by a hospital, infirmary, or clinic; however, emergency care for serious injuries must be available within no more than 3-4 minutes of the workplace if there is no employee on the site who is trained to render first aid.)

- If workers may be exposed to corrosive materials (e.g., in battery charging areas), provide facilities in the work area for quick drenching or flushing of the eyes and body.

- If employers are responsible for rendering medical assistance as part of their job duties, follow the additional requirements in OSHA’s Bloodborne Pathogens standard (29 CFR 1910.1030).

Incidental Chemical Spills*

To prevent spills, ensure chemicals are stored properly in the warehouse (See Hazardous Chemicals, above) and:

- Have a written spill control plan.

- Train workers how to clean up incidental spills, including how to protect themselves and properly dispose of used materials.

- Provide proper personal protective equipment and enforce its use.

* Incidental spills are situations where a spilled/released chemical can be absorbed, neutralized, or otherwise controlled at the time of release by workers in the immediate release area, or by maintenance personnel. If there is the potential for a substantial release, then emergency response operations may be subject to the Hazardous Waste Operations and Emergency Response (HAZWOPER) standard (29 CFR 1910.120).

Other issues may warrant consideration in a warehousing facility’s emergency plan, including, but not limited to: bloodborne pathogens; pandemic preparedness; unauthorized access to the facility; and workplace violence, including active shooter situations. Many types of emergencies can be anticipated in the planning process, which can help employers and workers plan for other unpredictable situations.

Note: Warehousing operations subject to certain standards are required to have an emergency action plan that complies with 29 CFR 1910.38. This may include operations that warehouse hazardous substances or that are subject to the provisions of the Process Safety Management of Highly Hazardous Chemicals (PSM) standard (29 CFR 1910.119), (e.g., due to presence of ammonia refrigeration systems), and the Hazardous Waste Operations and Emergency Response (HAZWOPER) standard (29 CFR 1910.120) due to presence of hazardous substances and the potential for substantial releases.

The following OSHA resources provide more detailed information regarding emergency planning:

- Emergency Preparedness and Response. This safety and health topics page provides information on how to prepare and train for emergencies and the hazards to be aware of when an emergency occurs.

- Evacuation Plans and Procedures eTool. This resource provides general guidance for implementing an emergency action plan. (Note: As noted above, some establishments may also need to develop an emergency action plan in compliance with 29 CFR 1910.38.)

- How to Plan for Workplace Emergencies and Evacuations. OSHA Publication 3088.

- Best Practices Guide: Fundamentals of a Workplace First-Aid Program. OSHA Publication 3317.

- Fact Sheet: OSHA’s Bloodborne Pathogens Standard.

- Most Frequently Asked Questions Concerning the Bloodborne Pathogens Standard. OSHA Standard Interpretation.

- Fact Sheet: Fire Safety. OSHA Publication FS 3527.

- Workplace Violence. This safety and health topics page provides information on assessing hazards and developing workplace violence prevention plans.

1910.147 The control of hazardous energy (lockout/tagout)

(c) General

(4) Energy control procedure.

(i) Procedures shall be developed, documented and utilized for

the control of potentially hazardous energy when employees

are engaged in the activities covered by this section.

Stress can be harmful to our health and increase mental health challenges. Mental health challenges can include clinical mental illness and substance use disorders as well as other emotions like stress, grief, feeling sad and anxious, where these feelings are temporary and not part of a diagnosable condition. While there are many things in life that induce stress, work can be one of those factors. However, workplaces can also be a key place for resources, solutions, and activities designed to improve our mental health and well-being.

Workplace stress and poor mental health can negatively affect workers through1:

- Job performance

- Productivity

- Work engagement and communication

- Physical capability and daily functioning

Statistics

- Nearly one in five US adults live with a mental illness2.

- Workplace stress has been reported to cause 120,000 deaths in the US each year3.

- Approximately 65% of U.S. workers surveyed have characterized work as being a very significant or somewhat significant source of stress in each year from 2019-20214.

- 83% of US workers suffer from work-related stress

54% of workers report that work stress affects their home life5. - For every $1 spent on ordinary mental health concerns, employers see a $4 return in productivity gains

Hazards/Precautions

In addition to cold stress, there are other winter weather related hazards that workers may be exposed to when performing tasks such as driving in the snow, removing snow from rooftops, and working near downed or damaged power lines.

- Winter Driving

- Work Zone Traffic Safety

- Stranded in a Vehicle

- Shoveling Snow

- Using Powered Equipment like Snow Blowers

- Clearing Snow from Roofs and Working at Heights

- Preventing Slips on Snow and Ice

- Repairing Downed or Damaged Power Lines

- Working Near Downed or Damaged Power Lines

- Removing Downed Trees

Winter Driving

Although employers cannot control roadway conditions, they can promote safe driving behavior by ensuring workers: recognize the hazards of winter weather driving, for example, driving on snow/ice covered roads; are properly trained for driving in winter weather conditions; and are licensed (as applicable) for the vehicles they operate. For information about driving safely during the winter, visit OSHA’s Safe Winter Driving page.

Work Zone Traffic Safety

Workers being struck by vehicles or mobile equipment lead to many work zone fatalities or injuries annually. Drivers may skid, or lose control of their vehicles more easily when driving on snow and/or ice covered roads. It is therefore, important to properly set up work zones with the traffic controls identified by signs, cones, barrels, and barriers, to protect workers. Workers exposed to vehicular traffic should wear the appropriate high visibility vest at all times, so that they can be visible to motorists (OSHA Letter of Interpretation, dated, August 5, 2009).

Learn more at: Work Zone Traffic Safety (OSHA QuickCard™) and Highway Work Zones and Signs, Signals, and Barricades (OSHA Safety and Health Topics Page).

Stranded in a Vehicle

If you are stranded in a vehicle, stay in the vehicle. Call for emergency assistance if needed, response time may be slow in severe winter weather conditions. Notify your supervisor of your situation. Do not leave the vehicle to search for assistance unless help is visible within 100 yards. You may become disoriented and get lost in blowing and drifting snow. Display a trouble sign by hanging a brightly colored cloth on the vehicle’s radio antenna and raising the hood. Turn on the vehicle’s engine for about 10 minutes each hour and run the heat to keep warm. Also, turn on the vehicle’s dome light when the vehicle is running as an additional signal. Beware of carbon monoxide poisoning. Keep the exhaust pipe clear of snow, and open a downwind window slightly for ventilation.

Watch for signs of frostbite and hypothermia. Do minor exercises to maintain good blood circulation in your body. Clap hands and move arms and legs occasionally. Try not to stay in one position for too long. Stay awake, you will be less vulnerable to cold-related health problems. Use blankets, newspapers, maps, and even the removable car mats for added insulation. Avoid overexertion since cold weather puts an added strain on the heart. Unaccustomed exercise such as shoveling snow or pushing a vehicle can bring on a heart attack or make other medical conditions worse.

Shoveling Snow

Shoveling snow can be a strenuous activity, particularly because cold weather can be taxing on the body. There is a potential for exhaustion, dehydration, back injuries, or heart attacks. During snow removal in addition to following the tips for avoiding cold stress, such as taking frequent breaks in warm areas, there are other precautions workers can take to avoid injuries. Workers should warm-up before the activity, scoop small amounts of snow at a time and where possible, push the snow instead of lifting it. The use of proper lifting technique is necessary to avoid back and other injuries when shoveling snow: keep the back straight, lift with the legs and do not turn or twist the body.

Using Powered Equipment like Snow Blowers

It is important to make sure that powered equipment, such as snow blowers are properly grounded to protect workers from electric shocks or electrocutions. When performing maintenance or cleaning, make sure the equipment is properly guarded and is disconnected from power sources.

Snow blowers commonly cause lacerations or amputations when operators attempt to clear jams with the equipment turned on. Never attempt to clear a jam by hand. First, turn the snow blower off and wait for all moving parts to stop, and then use a long stick to clear wet snow or debris from the machine. Keep your hands and feet away from moving parts. Refuel a snow blower prior to starting the machine; do not add fuel when the equipment is running or when the engine is hot.

Clearing Snow from Roofs and Working at Heights

Employers must evaluate snow removal tasks for hazards and plan how to do the work safely. Workers should be aware of the potential for unexpected hazards due to the weather conditions, for example, layers of ice can form as the environmental temperature drops, making surfaces even more slippery. A surface that is weighed down by snow must be inspected by a competent person to determine if it is structurally safe for workers to access it, because it may be at risk of collapsing. Snow covered rooftops can hide hazards such as skylights that workers can fall through. Electrical hazards may also exist from overhead power lines or snow removal equipment.

Employers can protect workers from these hazardous work conditions, for example, by using snow removal methods that do not involve workers going on roofs, when and where possible. Employers should determine the right type of equipment (ladders, aerial lifts, etc.) and personal protective equipment (personal fall arrest systems, non-slip safety boots, etc.) for the job and ensure that workers are trained on how to properly use them. For more information, see OSHA’s Hazard Alert: Falls and Other Hazards to Workers Removing Snow from Rooftops and Other Elevated Surfaces.

Preventing Slips on Snow and Ice

To prevent slips, trips, and falls, employers should clear walking surfaces of snow and ice, and spread deicer, as quickly as possible after a winter storm. In addition, the following precautions will help reduce the likelihood of injuries:

- Wear proper footwear when walking on snow or ice is unavoidable, because it is especially treacherous. A pair of insulated and water resistant boots with good rubber treads is a must for walking during or after a winter storm. Keeping a pair of rubber over-shoes with good treads which fit over your street shoes is a good idea during the winter months.

- Take short steps and walk at a slower pace so you can react quickly to a change in traction, when walking on an icy or snow-covered walkway.

Repairing Downed or Damaged Power Lines

Repairing and/or replacing damaged power lines in severe winter weather conditions are especially hazardous. A major hazard is snow, because the moisture can reduce the insulation value of protective equipment, and could cause electrocution. In these conditions de-energized work is safer, but if energized work must be done, qualified workers and supervisors must first do a hazard analysis that includes evaluating the weather conditions and identifying how to safely do the job.

Other potential hazards include:

- Electrocution by contacting downed energized power lines, or contacting objects, such as broken tree limbs, in contact with downed energized power lines.

- Fires caused by an energized line or equipment failure.

- Being struck or crushed by falling tree limbs, collapsing poles, etc.

When working on downed or damaged power lines, electrical utility workers should use safe work practices, appropriate tools and equipment (including personal protective equipment (PPE)). Extra caution should be exercised when working in adverse weather conditions. Learn more at: Contact with Power Lines (OSHA Construction eTool).

Working Near Downed or Damaged power lines

Assume all power lines are energized and stay clear of any downed or damaged power lines. Establish a safe distance from power lines and report any incidents to the responsible authority. Only properly-trained electrical utility workers can handle damaged power lines. Learn more at: Contact with Power Lines (OSHA Construction eTool) and Working Safely Around Downed Electrical Wires (OSHA Fact Sheet).

Removing Downed Trees

Clearing downed trees is a critical job during severe winter weather conditions. It is usually urgent to remove downed trees that block public roads and damage power lines. Emergency crews are often tasked with clearing downed trees.

Potential hazards include:

- Electrocution by contacting downed energized power lines or contacting broken tree limbs in contact with downed energized power lines. Learn more at: Line Clearance Tree Trimming Operations (OSHA Electric Power eTool).

- Falls from heights.

- Being injured by equipment such as chain saws (Chain Saw Safety (OSHA QuickCard™)) and chippers (Chipper Machine Safety (OSHA QuickCard™)).

Workers should wear PPE that protect them from the hazards of the tree removal tasks. Workers using chainsaws and chippers to clear downed trees should use: gloves, chaps, foot protection, eye protection, fall protection, hearing protection and head protection.

Only powered equipment designed for outdoor and wet conditions should be used. Use all equipment and tools (saws, chippers, etc.) properly and for the purpose that they are designed for. Ensure that equipment is always maintained in serviceable condition and inspected before use by a knowledgeable person that can identify any problems with the equipment. Do not use equipment that is not functioning properly. Equipment must have proper guarding (as applicable); safe guards must never be bypassed. All controls and safety features must function as designed by the manufacturer. Learn more at: Tree Trimming and Removal (OSHA QuickCard™).

You must be logged in to post a comment.